High Performance pin bushing excavator - Connecting pin in hydraulic excavators – Lanli

High Performance pin bushing excavator - Connecting pin in hydraulic excavators – Lanli Detail:

* Product Application

Committed to the production of construction machinery pin, the main parts used in the excavator are the connecting pin between the back end of the boom and the platform, the connecting pin between the platform and the cylinder, the connecting pin between the middle end of the boom and the cylinder, the connecting pin between the upper ear plate and the cylinder, etc, the application parts are shown below

* Specifications

Product specifications and technical requirements (excerpt) refer to the following table, can also meet the customer non-standard customization.

|

Material |

Diameter range |

length range /mm |

Tempering requirement |

Induction hardening requirement |

|||

|

Mechanical Property |

Hardness |

Surface hardness |

Layer depth |

||||

|

Tensile Strength |

Yield Strength |

||||||

|

N/mm2 |

N/mm2 |

HB |

HRC |

mm |

|||

|

45 |

45-185 |

103-1373 |

≥690 |

≥490 |

201-269 |

49-59 |

2 above |

|

40Cr |

45-155 |

118-1288 |

≥930 |

≥785 |

235-280 |

52-60 |

3-5 |

|

42CrMo |

45-160 |

128-1325 |

≥980 |

≥830 |

248-293 |

52-60 |

3-5 |

| Remark:The tempering requirements are mechanical properties or hardness, which can not be met at the same time. | |||||||

*Service & Advantage

According to the special requirements of customers, the current surface treatment methods are:

1)Hard chrome plating,NSS method in ISO 9227 (GB/T 10125) is adopted to meet the requirements of 72 hours salt spray test.

2)Zinc plating, yellow zinc salt spray test requirements≥96 hours in accordance with ATM B633 standard.

3)MAGNI 565 treatment,salt spray test reach 480 hours.

4)Electrophoresis,salt spray test reach 250 hours.

5)Special surface treatment can be customized.

*Our Factory

L ANLI was founded in 1987, has become the most competitive enterprise with the highest potential in the domestic and foreign construction machinery industry. It has Hefei L ANLI

LANLI machinery Manufacturing Co., Ltd. LANLI is the professional construction machinery parts manufacturers, cooperating with Hitachi, Sumitomo, Volvo, JCB, XCMG, SDLG, Kangmingsi and other world-class customers, the main products are the pins, structural parts, etcs.LANLI will give you our best seivice and high quality products, common development with you is our ultimate target.

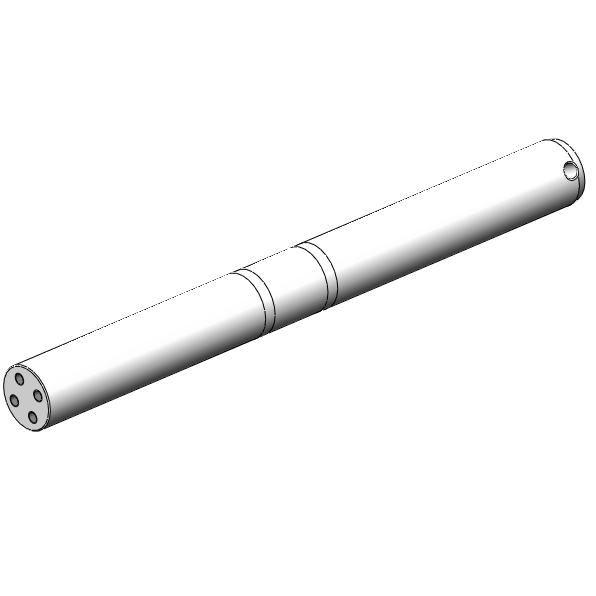

Product detail pictures:

Related Product Guide:

We take customer-friendly, quality-oriented, integrative, innovative as objectives. Truth and honesty is our management ideal for High Performance pin bushing excavator - Connecting pin in hydraulic excavators – Lanli , The product will supply to all over the world, such as: Rotterdam, Israel, Swiss, we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

The company's products can meet our diverse needs, and the price is cheap, important is that the quality is also very nice.