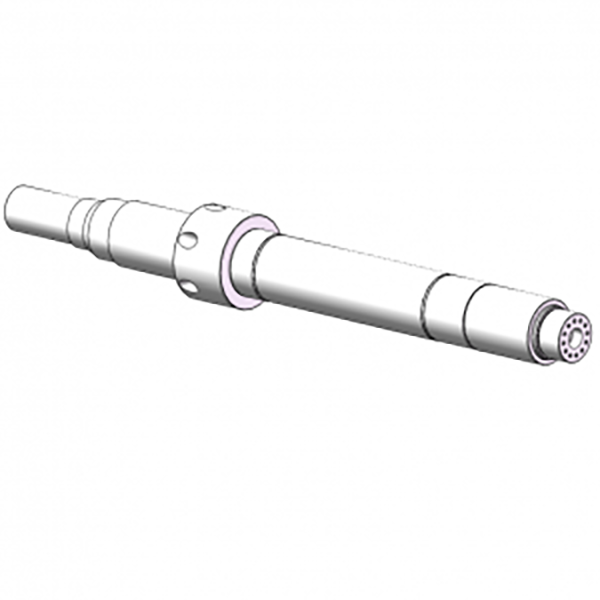

Hot-selling pin on loader bale spear - Transmission shaft for Hot compact excavator hydraulic excavators – Lanli

Hot-selling pin on loader bale spear - Transmission shaft for Hot compact excavator hydraulic excavators – Lanli Detail:

* Product Application

Applied to road equipment in the field of construction machinery, this product is mainly used to connect the interface of asphalt paver.

* Specifications

Product specifications and technical requirements (excerpt) refer to the following table, can also meet the customer non-standard customization.

|

Material |

Tempering Requirement |

||||||

|

Mechanical property |

Hardness |

||||||

|

Tensile Strength |

Yield Strength |

Elongation |

Reduction of area |

Impact energy |

Notched bar impact strength |

||

|

N/mm2 |

N/mm2 |

% |

% |

J |

J/cm² |

HB |

|

| Forging 40CrNiMoA |

>980 |

>835 |

≥12 |

≥55 |

≥78 |

≥98 |

240-270 |

| Remark:The tempering requirements are mechanical properties or hardness, which can not be met at the same time. | |||||||

*Service & Advantage

According to the special requirements of customers, the current surface treatment methods are:

1)Hard chrome plating,NSS method in ISO 9227 (GB/T 10125) is adopted to meet the requirements of 72 hours salt spray test.

2)Zinc plating, yellow zinc salt spray test requirements≥96 hours in accordance with ATM B633 standard.

3)MAGNI 565 treatment,salt spray test reach 480 hours.

4)Electrophoresis,salt spray test reach 250 hours.

5)Special surface treatment can be customized.

6)Implemented according to GB/T6402 “Steel Forgings Ultrasonic Testing Method” quality grade 4.

*Our Factory

We are committed to intelligent automatic production lines, welding robot production lines, laser cutting machines, implementing digital lean management models, mastering core innovation technologies, and with multiple invention patents and practical program model patents to ensure that the level of technical capabilities is always at the forefront of the industry at the forefront of the industry.With its own technology, superior quality and integrity, to provide customers with superb products and professional services, has won a wide range of credibility at home and abroad.

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, great high-quality and fantastic religion, we win great track record and occupied this area for Hot-selling pin on loader bale spear - Transmission shaft for Hot compact excavator hydraulic excavators – Lanli , The product will supply to all over the world, such as: Zimbabwe, Georgia, Hungary, Adhering to the management tenet of Managing Sincerely, Winning by Quality, we try our to provide excellent products and service to our clients. We look forward to making progress together with domestic and international clients.

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!