OEM manufacturer mini excavator bucket pin sizes - High performance pin for intelligent hydraulic excavator – Lanli

OEM manufacturer mini excavator bucket pin sizes - High performance pin for intelligent hydraulic excavator – Lanli Detail:

* Product Application

Committed to the production of construction machinery pin, the main parts used in the excavator are the connecting pin between the back end of the boom and the platform, the connecting pin between the platform and the cylinder, the connecting pin between the middle end of the boom and the cylinder, the connecting pin between the upper ear plate and the cylinder, etc, the application parts are shown below

* Specifications

Product specifications and technical requirements (excerpt) refer to the following table, can also meet the customer non-standard customization.

|

Material |

Diameter range |

length range /mm |

Tempering requirement |

Induction hardening requirement |

|||

|

Mechanical Property |

Hardness |

Surface hardness |

Layer depth |

||||

|

Tensile Strength |

Yield Strength |

||||||

|

N/mm2 |

N/mm2 |

HB |

HRC |

mm |

|||

|

45 |

45-185 |

103-1373 |

≥690 |

≥490 |

201-269 |

49-59 |

2 above |

|

40Cr |

45-155 |

118-1288 |

≥930 |

≥785 |

235-280 |

52-60 |

3-5 |

|

42CrMo |

45-160 |

128-1325 |

≥980 |

≥830 |

248-293 |

52-60 |

3-5 |

| Remark:The tempering requirements are mechanical properties or hardness, which can not be met at the same time. | |||||||

*Service & Advantage

According to the special requirements of customers, the current surface treatment methods are:

1.Hard chrome plating,NSS method in ISO 9227 (GB/T 10125) is adopted to meet the requirements of 72 hours salt spray test.

2.Zinc plating, yellow zinc salt spray test requirements≥96 hours in accordance with ATM B633 standard.

3.MAGNI 565 treatment,salt spray test reach 480 hours.

*Our Factory

With its own technology, superior quality and integrity, to provide customers with superb products and professional services, has won a wide range of credibility at home and abroad.

We adhere to the”Mutual benefit and win-win, profit and people” business philosophy, customer value to achieve the ultimate goal of service. Since its inception, the People’s Bank of China has always maintained AAA enterprise credit rating, passed the ISO9001 quality system professional certification, ISO14001 environmental system certification, and Y32-63T four-column hydraulic machine CE certification; Integrity and professional qualifications, excellent and dedicated quality, stability and superb quality, has won the full trust and praise of partners and customers.

Our strong technical force, there are more than 40 senior R & D personnel, Jiangsu Province science and technology department as”Jiangsu (Blue) Press Technology R & D Center”, jiangsu provincial department of Education as a provincial-level enterprise graduate workstation. The company takes innovation as the primary development strategy, through unremitting technology, management and service innovation, enhance the advantage of process equipment, product technology content and brand market trust; Blue Power 10 series of more than 100 varieties of hydraulic press with its superior cost-effective, best-selling provinces, cities, autonomous regions, and exported to Europe, the United States, Russia and Southeast Asia, the Middle East; It is widely used in aerospace, electric appliances, rail transit, ships and automobiles, energy and petrochemical, building materials, electronic manufacturing and other fields.

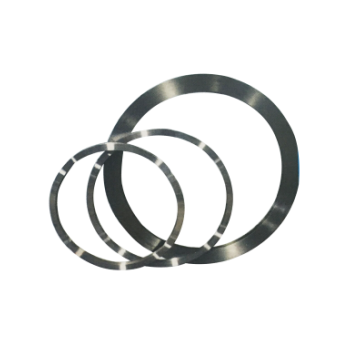

Product detail pictures:

Related Product Guide:

Persisting in High high quality, Prompt Delivery, Aggressive Price, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for OEM manufacturer mini excavator bucket pin sizes - High performance pin for intelligent hydraulic excavator – Lanli , The product will supply to all over the world, such as: Myanmar, Georgia, Botswana, We welcome an opportunity to do business with you and hope to have pleasure in attaching further details of our products. Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.